Making Of #1: Octopus Pocket Holsters

Making custom pieces is always fulfilling. It’s really exciting when someone approaches me with a great concept and encourages me to expand on it, offering me the freedom to play and create. This was one of those projects. The original vision was for a pair of pocket holsters, with an Octopus as the back straps. I had never made holsters and it was exciting and inspiring to take the challenge and opportunity to try something new. Here is a little visual journey into the process:

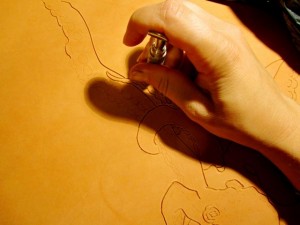

2. The leather is “cased” to a certain moisture content to receive the tooling impressions, this takes about 24 hours. The image is then traced to the prepared leather.

3. The outlines of the design are then carefully cut into the leather with a special knife. The Swivel Knife has a pivot to allow curved and continuous cuts. Any mistakes cannot be undone, so it’s really important to get it right!

4. The outlines of the design are beveled using small tools and a maul (hammer) to bring the design into relief. Other tools, including modeling/sculpting spoons are used to add definition, texture and detail. This took about 8 hours!

8a. The finished piece! Once all of the pocket components are tooled and painted they are hand laced together and all of the assembly is done. The pockets tops are soft, buttery deer hide and sting ray.

this is awesome! i’m very impressed with this creation. thank you for making it available to view